Intro

Industrial partitions cover a wide range of partitioning and materials for food production, electronics, pharmaceutical, biological, radioactive, machine confinement, storage, etc ....

Advantages

- Faster implementation than conventional desktop partitioning: Time saving

- Lower price than office partitioning: Reduced budget

Components of industrial partitions

The domain is extremely vast since it includes a large number of components such as:

Sheet steel sandwich panels with synthetic foam core or rock wool (fire resistant) for workshop offices, clean and sterile pressurized rooms.

Perforated sheet steel sandwich panels with rock wool core for partitioning and acoustic machine casing

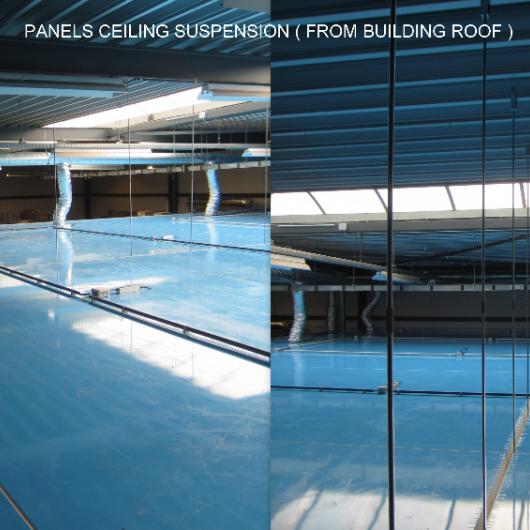

Acoustic baffles suspended from ceilings and roofs or attached to walls to reduce ambient noise in production or office areas.

Thin sandwich panels in synthetic sheets with or without metal core (finishing trim)

Gyprok and special paints for good fire resistance (around or on metal beams)

Mesh or sheet panels (machine guards and warehouses)

Panels made of transparent strips for thermal insulation (cold and hot) and dust in frequent traffic areas (men and machines) while maintaining maximum visibility

Often complementary steel platforms (space saving) industrial or office partitions

To this are added all types of shutters and doors pivoting, folding, sliding, rigid, flexible, manual or electric controls, etc ....

All ancillary works such as flooring, false ceilings, lighting, electricity, data, plumbing, heating, air-co, HVAC, showers, sanitary, paintings are of course logically part of our core business.

It is clear that all of its applications must often be combined to form an all optimally responsive to the needs of our client.